|

|

Post by Mike B on Jun 22, 2010 21:52:57 GMT 1

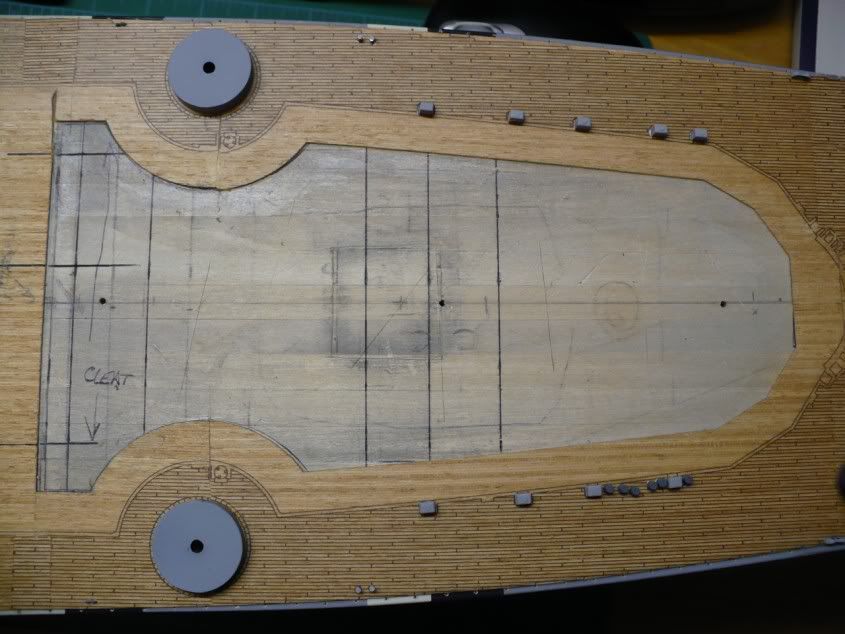

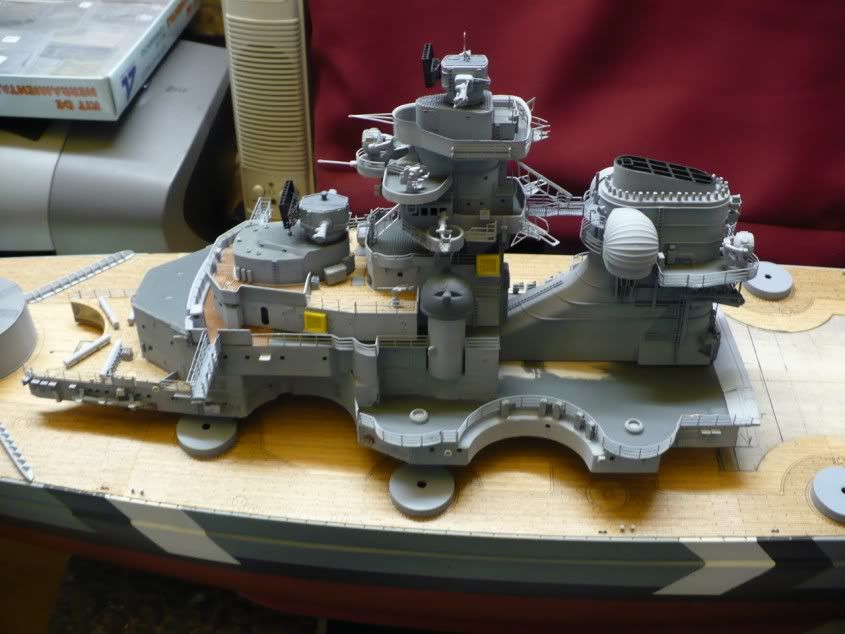

I decided to follow Grant's suggestion of doing as much rigging as possible before gluing the superstructures to the deck. After gluing the main deck coverings in place, I placed the main fore and aft superstructures in their final positions and taped them down. I then drilled three, 2mm holes through the centre lines of each superstructure into the deck, where they would not be seen. I then fitted toothpicks into these holes to form locating pegs.  I was now able to continue construction on the superstructures knowing that they would fit onto the deck in the exact same position every time. all the parts that fitted around the superstructures were glued only to the deck and not the side walls of the superstructures. This allowed me to continue with the build without having to go back and glue parts on after the superstructures were finally glued in place.    |

|

|

|

Post by Mark on Jun 24, 2010 9:13:10 GMT 1

Nicely described Mike. worth a K, and I might do the same myself.

|

|

|

|

Post by Mike B on Jun 27, 2010 21:04:11 GMT 1

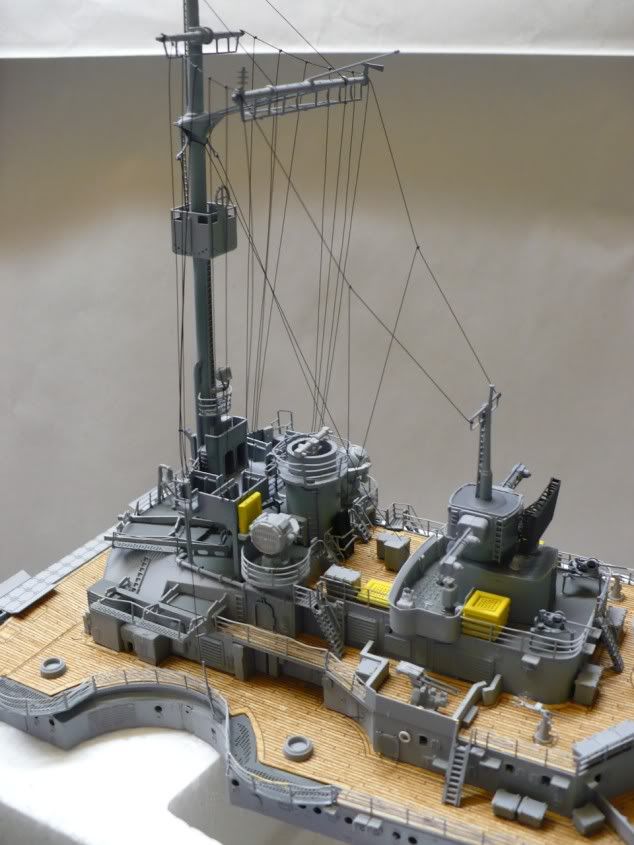

A belated K for Grant! What a pleasure it was to do the rigging off the boat! I used a piece of polystyrene on my turntable and mounted the superstructures on it so that I could rotate them.   The superstructures were then glued in place to complete the final rigging.  For anyone doing rigging on this or any sailing ship, I would recommend purchasing a pair of these nail clippers. They allow you to cut the rigging right up against the knot without leaving a "tail". In South Africa, you can get them from the "Crazy store". Elsewhere, any chemist such as "Boots".  |

|