|

|

Post by Mike B on Oct 15, 2007 18:07:43 GMT 1

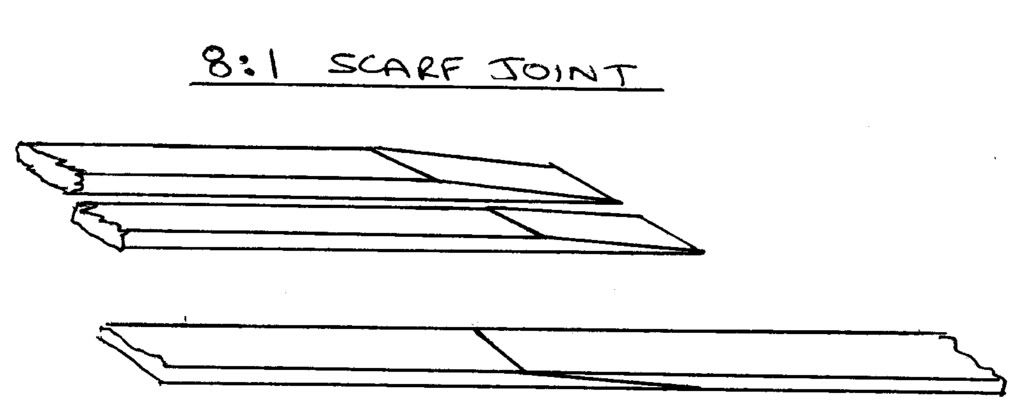

Hi Guys, Although most of you have already done your first planking, Australia and South Africa still have that pleasure to come! By the very nature of partworks, the plank lengths are limited to the size of the magazine. I am thinking of joining the planks together to form planks the length of the hull using scarf joints as per the following diagragm. Two planks are laid together side by side and an approx 8:1 angle planed or sanded on the ends. The planks are then joined together with CA glue to make one longer plank. The reasoning behind this is to get a smoother curve to the planking over the ribs as a single plank gives a smoother curve over ribs than two planks joined on a rib. I know that Markus sourced his own planks of the correct length but this incurred additional cost. Does anyone have any thoughts on this method?  Mike B |

|

|

|

Post by markus on Oct 15, 2007 19:11:10 GMT 1

good idea - hope there's still enough total length after several overlaps...

markus

|

|

|

|

Post by napoleon on Oct 15, 2007 19:36:02 GMT 1

For the 2nd planking, I am getting 7mm x 1mm x 1metre strips. This will give a much smoother finish in my humble opinion and less fiddling about.

|

|

|

|

Post by Mike B on Oct 15, 2007 20:29:59 GMT 1

Can anyone tell me about the planks supplied: are they the exact length between frames or are they a bit longer ?

Mike B

|

|

|

|

Post by napoleon on Oct 15, 2007 20:58:29 GMT 1

They are a bit longer than required, Mike.

|

|

|

|

Post by swanrail on Oct 15, 2007 22:48:11 GMT 1

With the first planks it was, of necessity, required to join the planks on a rib. However, with the second set it should be possible to stagger the joints, hence getting a smoother finish.

Again, with this model being painted, it should be possible to make good with fillers any blemishes, not possible with those ships left in a varnished state.

|

|

|

|

Post by napoleon on Oct 15, 2007 22:57:43 GMT 1

Very valid points there, Swanrail

|

|

|

|

Post by mattyb on Oct 18, 2007 8:36:49 GMT 1

Is the planks supplied the same as you wpuld get from a hobby shop? So if we wanted to jump ahead of the game a little could we?

|

|

|

|

Post by Greg on Oct 18, 2007 11:12:00 GMT 1

Hi Guys, I am thinking of joining the planks together to form planks the length of the hull using scarf joints as per the following diagragm. Two planks are laid together side by side and an approx 8:1 angle planed or sanded on the ends. The planks are then joined together with CA glue to make one longer plank. [ Mike B Mike, While I'm not intending to do as you plan I has been thinking of using a few full length planks on my model. The idea is to try and reduce the chances of warping by locking the keel & frames into place. The keel of my model already has a slight "hog" and I want to stop it from turning into a real pig  . Hopefully by fixing the keel to a base plate and laying 3-4 full length planks either side everything will be fixed in place and unable to move out of alignment. Good luck with your plan, hope you achieve the result you desire. Greg. |

|

|

|

Post by Mike B on Oct 18, 2007 16:55:39 GMT 1

Hi Greg, The reason behind the full length planks was that on the Titanic, the planks were joined on a rib where the hull shape curved dramatically towards the bow. This resulted in a sharp bend in the hull sides over the rib. A full plank would have resulted in a much smoother transition as the curve over the rib would have been balanced on both sides of the rib. Hope this is clear, Mike B  |

|

|

|

Post by nm on Oct 18, 2007 17:27:30 GMT 1

Have a great day!

NM

|

|

|

|

Post by Greg on Oct 19, 2007 7:02:44 GMT 1

Hi Greg, The reason behind the full length planks was that on the Titanic, the planks were joined on a rib where the hull shape curved dramatically towards the bow. This resulted in a sharp bend in the hull sides over the rib. A full plank would have resulted in a much smoother transition as the curve over the rib would have been balanced on both sides of the rib. Hope this is clear, Mike B Hi Mike, Point taken and it is a good point. A hull should have nice flowing lines without any sharp bends and your right full length planks would eliminate this problem. If I was to try to create the full length planks using the technique you described my main concern would be whether or not it is possible to get really nice clean joins and there is going to be a lot of them. Getting the scarf joints evenly matched could turn out to be a real chore but I hope that you can manage it. I can appreciate your hesitation in buying more material as Markus did, this model is expensive enough as it is without adding extra cost to it. While I haven't yet made a final decision yet I may use the shorter Amati supplied planks to plank amidships and then have longer planks running fore and aft. Hopefully this would cut down on the cost of addition planks. The length of plank required in this case would be about 500mm(?) and buying 1m planks and cutting them in half would be a relatively inexpensive way to do it. I haven't come across planks longer than a metre in Oz so for me buying planks which run the full length of the hull is out of the question anyway. All of this is of course assuming that Amati supplies us with standard size material for the first planking which is usually 1.5mm x 5mm. Thanks for sharing your idea, its all food for thought  . Regards Greg. |

|

|

|

Post by Mike B on Oct 19, 2007 13:38:20 GMT 1

Hi Greg,

The scarf joints are really quite easy to do. Lay two planks together side by side, ends level on the edge of the table. Using a sanding block, sand the angle on both planks together. As long as the sanding block is level and not tilted to one side, the angle will be the same shape on both planks. The angle is not critical (8 to1 is only a guide). Now turn one plank over and glue it to the other one using a straight edge alongside the two planks as a guide. The joint does not have to be perfect as the first planking gets sanded anyway before the second planking goes on.

Try it with two pieces of scrap planking and you will see how quick and easy it is!

Mike B

|

|

|

|

Post by Greg on Oct 20, 2007 6:16:56 GMT 1

Mike,

No worries, I'll probably give it a go. As long as the joint is kept away from where the plank needs to bend sharply I can't see any problems with your idea.

The only reason I say "keep the joint away from sharp bends" is because the joint will be more rigid than the rest of the plank and therefore more breakable due to the CA.

Greg.

|

|

|

|

Post by popeye on Nov 9, 2007 16:14:12 GMT 1

I have posted some more pictures showing my Bismarck to date. It shows the start of the second hull planking using the long mahogany strips, how I am fixing the middle propellor as a freewheeling (unpowered) prop, the fixing of the propshafts into the frames inside the boat, a sanding block and roll of sandpaper, plank bender, and how I have secured the decks using quick release quarter turn dzus screws. click on www.flickr.com/photos/commander-popeye/and either just scroll through the pictures or select the Bismarck as at 9 Nov 07 set. |

|