|

|

Post by eric on Sept 1, 2007 13:45:20 GMT 1

|

|

|

|

Post by nemesis on Sept 1, 2007 14:41:34 GMT 1

That looks pretty much like what I've got.

|

|

|

|

Post by eric on Sept 1, 2007 14:45:26 GMT 1

Yes, the destructions are particularly vague for that bit, but this seemed the logical way to do it.

I'll say it shall I?

"It's logic captain....but not as we know it!!"

|

|

|

|

Post by napoleon on Sept 1, 2007 17:16:09 GMT 1

Super stuff Eric looks really good, thats the way to do it. Only one point to make, where will your 2nd planking stop?

Shall I say It?

Beam me up Scotty!! ;D ;D

Napoleon

|

|

|

|

Post by eric on Sept 1, 2007 17:44:44 GMT 1

I'm still debating about the second planking. Looking at the hull at this point, I can fully see why Markus has opted to second plank up to deck level, it would look so much better I think, but I have plenty of time to wait. there are quite a few here that are much further on that us, so I shall just wait and see what they do, I think!  |

|

|

|

Post by napoleon on Sept 1, 2007 18:30:00 GMT 1

Eric,

I like the way you have done things, and if the 2nd planking goes level with the top of the deck, then it looks like the runner (cant think of better name) upon which the hand rails are situated, would hide the top of the 2nd planking, umm, I think!!!

BTW, nice sharp photos.

Napoleon

|

|

|

|

Post by eric on Sept 1, 2007 19:06:42 GMT 1

The rails are the main problem, I think.

They must be very fragile and if they are on the hull rather that being lifted clear with the deck, then they could end up being bent and snapped off.........ouch!!

|

|

|

|

Post by markus on Sept 1, 2007 19:52:56 GMT 1

i will put the main switch and the charging socket in a place i can access wihout having to remove the deck. this will hopefully extend the lifetime of the railings  cheers markus |

|

|

|

Post by swanrail on Sept 2, 2007 0:05:21 GMT 1

Looking good Eric, and the same as mine, so if we are wrong according to Hachette, we shall all go down together!!!

I am very sceptical about the second planking as they say in issue that the upper section of the hull will NOT have a second layer, but of course no details on what will happen there. I am also not sure about the solution that Markus had of extending the second planking upwards and leaving the rails on this part,

which is why I fitted the reinforcing strips along the present top planks, this improves the watertightness of the hull, carries my magnetic catch system, and should allow me to fit the rails onto the removable part with much less chance of damage in use. Unfortunately, time will only tell (many, many weeks away) if I am right or not.

My biggest grouse of all the part work models I have made so far (Titanic, Victory and Bismarck) is that they never give us decent plans to work to, showing what is likely to happen. The Titanic had at least a crude plan at the start, and, when nearly finished, a better plan - but too late. Thank god for the Germans, although even they are not enough advanced to get the full picture either.

|

|

|

|

Post by markus on Sept 2, 2007 9:27:10 GMT 1

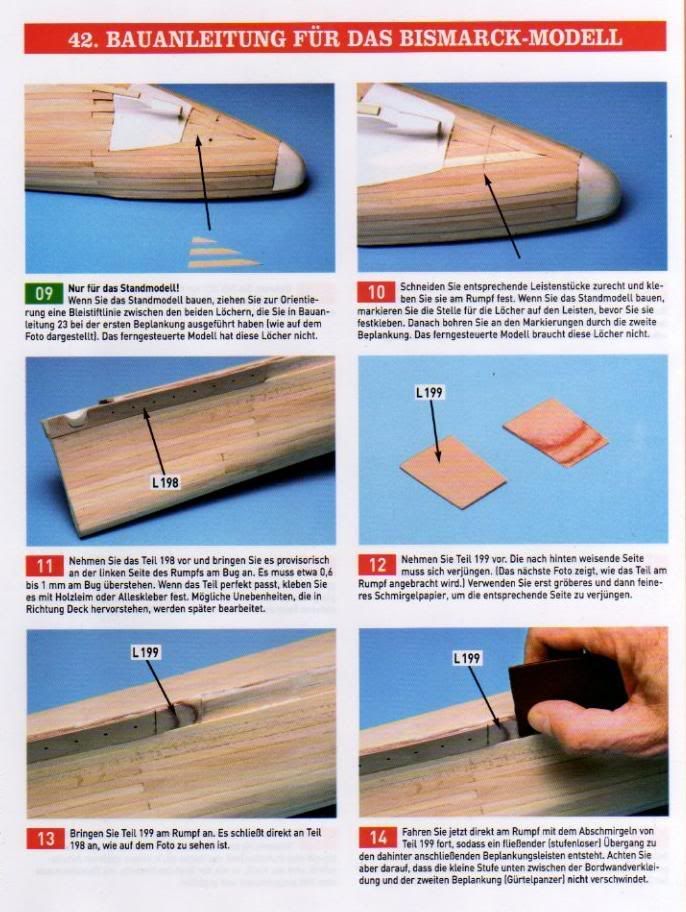

I am very sceptical about the second planking as they say in issue that the upper section of the hull will NOT have a second layer, but of course no details on what will happen there. nothing will happen there...(iss 42, 10 weeks ago)   |

|

|

|

Post by Mark on Sept 2, 2007 9:40:42 GMT 1

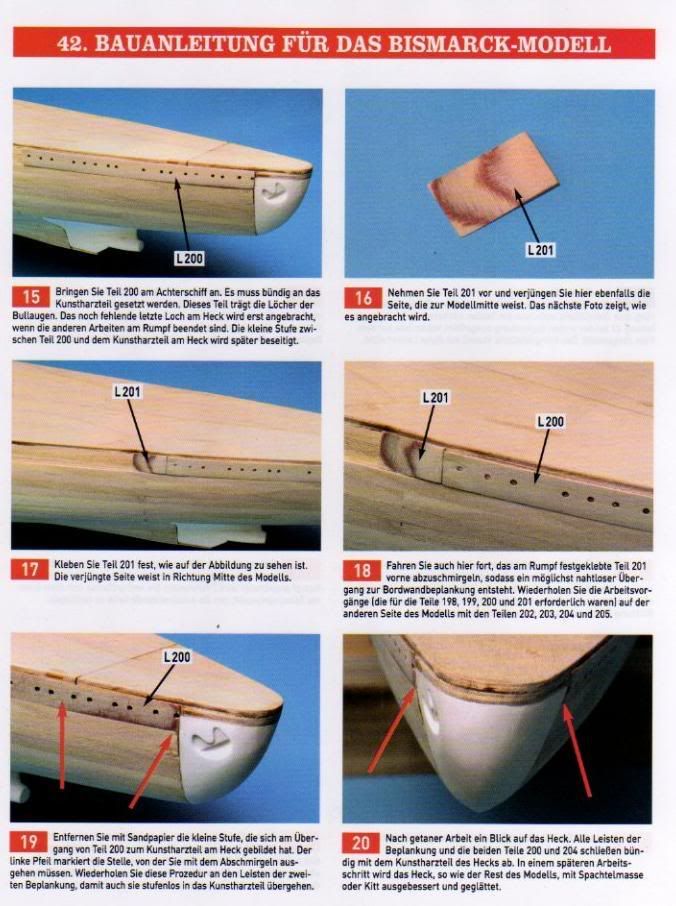

Excuse me for being cynical, but that looks like a cock-eyed way of merging the ply sheet with the port holes into the planking in the middle. Tapering a bit of ply down to nothing seems a hard way of going about things.

How's this for a plan. Forget about the planking at the top of the hull, between frame 43 & the small "framettes" 51. Leave a gap there. When you come to add the ply parts L200, add them normally, then put a ply filler in to fill the gap previously left. That avoids having to taper the ply part 201 down to wafer thin.

Do the same thing at the bow, but obviously the deck will have to be fitted afterwards.

What to you guys reckon ? Good plan, or doomed to failure ?

|

|

|

|

Post by mattyb on Sept 14, 2007 19:09:33 GMT 1

Sorry guys not sure if this has been asked, hey and I did take thew time to find the best spot for the question Are the metal planking clamps better than the plastic? As I have been cootoned on to 10 metal ones for $20 which is about 8.37585 GBP to the point. lol (a big shout out to XE.com)

lol

|

|

|

|

Post by gerrybuilt on Oct 16, 2007 1:02:39 GMT 1

Hi All,

I've seen the German mag. via internet and the second planking instructions. There does not seem to be any mention of the bevel on the top of the side armour. In our mag. there is much made of the side armour and the way it is made and fixed to the ship.

Now, I have seen and read a lot of stuff about this model and how some of us are so concerned about getting every little detail correct.

My question is; Why no-one has so far mentioned this fundamental detail?

Markus, how about it? Are you going to taper your armour?

I need to know.

|

|

|

|

Post by Guest on Oct 16, 2007 8:33:51 GMT 1

Wait until you see hull portholes on the model compared to the actual ship! There are certainly accuracy problems as the german forums will tell you, only thing you can do is put right what you know is wrong yourself  |

|

|

|

Post by Achtung!! on Oct 16, 2007 10:35:22 GMT 1

[quote author=eric board=planking thread=1180365370  [/quote] Mine doesnt look like this!!!  |

|